Polished Concrete Flooring & Cement Polishing

PLEASE NOTE: Minimum Job Size 800 sq. ft.

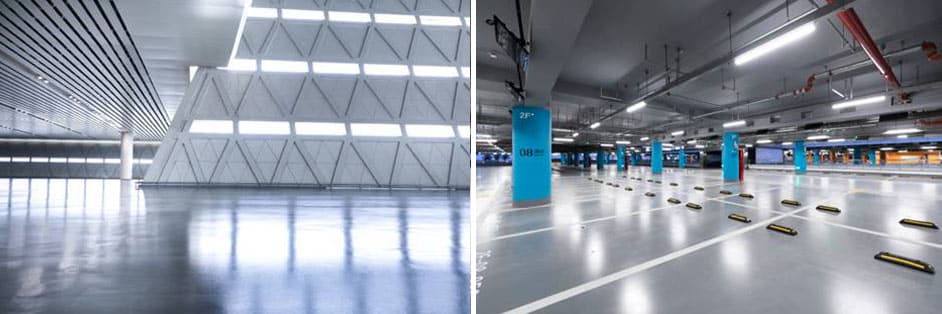

Beautiful & Practical

Polished Concrete Floors

Industrial, Commercial, and Residential Concrete/Cement Polishing in the Bay Area.

Economical

Many people are turning to cement polishing because of the low maintenance and longevity of this floor type.

For long-term cost savings, cement polishing is one of the best answers. The maintenance of a polished concrete floor amounts to giving it a dry, dust mop and a wet mop – that’s it!

Sustainable

Apart from our polished concrete floors’ fantastic look, they are amazingly durable while helping you maintain a low carbon footprint.

The durability of our polished concrete floors makes them ideal for industrial purposes. And for residential properties, we design livable and comfortable floorings for families of diverse shapes and sizes.

Growing Trend

Industry estimates indicate that polished concrete installations make up 15 to 20 percent of all new flooring systems installed each year.

These numbers are likely to continue rising, but you may wonder why more and more businesses are turning to polished concrete for their industrial flooring needs.

WHY CHOOSE US?

Our experience in maintaining the interiors of offices, high-tech, and retails spaces spans over 35 years of continuous service in the Bay Area.

We hold certificates for concrete grinding, polishing, staining, and repairs. We also continue to attend training courses from equipment and chemical manufacturers to stay updated with the newest industry products and trends.

We belong an support industry associations that set high professional standards for quality, safety, and environmental best practices.

Our Concrete/Cement Flooring Services

Our concrete flooring services are perfect for a wide variety of commercial properties.

We offer services for industrial properties, warehouses, manufacturing facilities, retail properties, offices, public bathrooms, restaurants and bars, breweries and vineyards, and more.

Our team of experienced professionals can help you choose the perfect finish for your space, from a flat look to a highly polished sheen.

We also offer sealing, staining, and coloring services to create the perfect look for your property.

Grinding & Polishing

We offer a variety of levels of polish, from a flat look to a highly polished sheen, so you can choose the perfect look for your space.

Flat (Stopping Below 400 Grit):

This is the perfect option if you are looking for a rustic or industrial look. The stopping below 100 grit leaves the floor with a rougher texture, which can add character to any space.

Satin (Stopping Below 800 Grit):

This is a good option if you want a more matte finish that will still hide imperfections. It is also a good choice if you are looking for something that is easy to maintain.

Semi-Gloss (Stopping Below 1500 Grit):

This is a great middle ground option. It provides some shine and reflection while still hiding imperfections.

Gloss (Up to 3000 Grit):

This is our most popular option and it creates a deep, rich shine. It also hides imperfections well and is easy to maintain.

Sealing

Once the grinding is complete, we will apply a densifier to the floor. This chemical reacts with the concrete to create a harder, more durable surface. After the densifier has had time to soak into the concrete, we will then begin polishing the floor. We use progressively finer grits of diamond pads to polish the floor until it has a glossy finish. Finally, we apply a sealer to the floor to protect it from stains and footprints.

Adding Color & Staining

Stained Concrete:

Staining concrete is a popular option because it can mimic the look of more expensive materials like marble or stone. Plus, it’s easy to achieve consistent results with staining.

Tinted Sealer:

A tinted sealer is essentially clear sealer with a dash of color added to it. Tinted sealers are great if you want to add a hint of color to your floors without changing the entire look of the space.

Dyes:

Dyes are similar to stains in that they can be used to create looks that mimic more expensive materials like wood or stone. however, dyes don’t penetrate as deeply into the concrete as stains do, so they’re not as durable.

Commercial Services

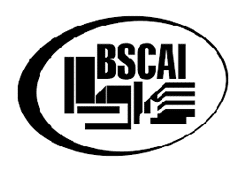

Industrial Properties

Warehouses

Manufacturing Facilities

Retail Properties

Offices

Public Bathrooms

Restaurants & Bars

Breweries and Vineyards

Residential Uses

Kitchens

Bathrooms

Living Areas

Garages

Utility Rooms

Patios

Balconies

Entryways

Driveways

Get Started Now!

You deserve the beauty of polished concrete.

Our Clients:

These organizations have given us their trust.

Our 4-Step Process to Achieving Polished Concrete Floors

At Transpacific Building Maintenance, we specialize in polished concrete floors. We are always perfecting our process to make sure that our customers are happy with their purchase.

STEP ONE: PREPARE THE SURFACE

The first step in our process is to prepare the surface of the concrete. This includes removing any old sealers or finishes, as well as filling any cracks or pits that may be present. Once the surface is prepped, we can move on to grinding.

STEP TWO: GRIND THE FLOOR

In order to get the desired appearance, we use a variety of different grit diamond pads to grind the floor. We begin with a coarse grit pad to remove any imperfections, and then progress to finer and finer grits until we achieve the desired level of polish.

STEP THREE: APPLY STAIN (OPTIONAL)

If the client desires a specific color, we can stain the cement accordingly. We have a wide variety of stains to choose from, so we are sure to be able to find one that fits the vision for your project.

STEP FOUR: SEAL THE FLOOR (OPTIONAL)

Once we have achieved the desired appearance, we can seal the concrete if desired. Sealing protects the floor from wear and tear and makes it easier to keep clean. Polished concrete floors are a beautiful and durable option for any property owner in Bay Area. If you are interested in having polished concrete floors installed in your home or office, please do not hesitate to contact Transpacific Building Maintenance. We would be more than happy to walk you through our process and answer any questions you may have.

State-of-the-Art Equipment & Products

We use the state-of-the-art tools, equipment, and products to tackle projects with any significant amount of square footage. We have a number of concrete polishing machines in our lineup. In addition to our grinders and dust shrouds, we also use consumables, air scrubbers, and industrial vacuums to create a smooth, durable finish on your concrete floors.

Concrete polishing is an art form that requires the right tools, equipment, and products. If you’re in the Bay Area and looking for a reliable contractor to handle your next project, give us a call today!

WHY IS POLISHED CONCRETE

FLOOR SO HOT RIGHT NOW?

Polished concrete flooring remains an ideal choice for people and businesses. With limitless design options, custom color choices, and the ability to match any style, polished concrete flooring is an excellent decorative choice.

It provides large open spaces with a unifying aesthetic which offers an uninterrupted transition from interior to exterior. Whether you desire it for your home or industrial and commercial facilities, it provides many benefits.

Polished concrete is ideal for commercial and industrial facilities such as hotel lobbies, factories, warehouses, automotive shops, offices, and even luxury residential properties.

THE BENEFITS OF POLISHED CONCRETE:

Prolonged Service Life

Polished concrete can resist heavy traffic like the legs of household furniture in homes or a forklift operating in industrial and commercial facilities. That’s not all; the polished concrete is resistant to damage from chemical and oil spills. Since polishing enables the concrete to breathe, there is no need to worry about issues arising due to moisture.

A Professional Image

The beauty of polished concrete undoubtedly promotes a professional image for most organizations in any environment. It promotes a clean appearance without in any way limiting its durability or longevity. This look gives the business a fresh and modern appeal.

It Lowers Cost

Don’t forget that the substrate and the finished product here are your pre-existing concrete. This single factor lowers the cost for businesses when polishing their floor. It adds to the overall savings resulting from the reduced maintenance costs of polished concrete flooring. Polished concrete reduces energy and maintenance costs by improving ambient lighting and reducing the need for regular floor maintenance such as machine scrubbing, sealing, and refinishing.

Improved Reflectivity and Ambient Lighting

The reflective properties of a polished concrete floor maximize lighting in facilities. Improved lighting reduces the cost of energy bills and increases safety. This is one of the remarkable features of polished concrete floors. Most office buildings and businesses love the reflectivity of the polished concrete surface. It brightens the workplace by reflecting artificial light within the business facility. Apart from eliminating the need for extra electricity to brighten up the office environment, it promotes a lively workplace.

Customizable

Do you have any unique shape, color, or features in mind? Polished concrete is the perfect solution for you. We can provide you with a design that suits your personal or corporate needs. We can design and color your concrete floors to suit your needs while exposing the concrete’s natural beauty.

Reduced Maintenance

Another exciting feature of polished concrete floors is their ease of maintenance. Most floor systems, including tile and linoleum, require aggressive scrubbing to maintain a sanitary environment and clean appearance. Polished concrete surfaces are tightly compacted to reduce the development of stains. At the same time, they do not require any waxing or stripping treatments to maintain their sheen. To ensure the continued smoothness and shine of the concrete, you can make use of other products.

A Stain-Resistant Surface

The process of densifying and sealing the surface transforms a concrete floor into a smooth surface that protects against contaminants, preventing them from penetrating the surface.

Improved Slip Resistance

Polished concrete, though shiny on the surface, does not create a slippery floor. The benefits of mechanically grinding and flattening the floor increase the coefficient of friction when compared to ordinary concrete.

LEED Friendly

Polished concrete requires fewer cleaning chemicals to maintain. It also typically does not contain volatile organic compounds (VOCs). Less dependence on chemicals makes it friendly for any U.S. Green Building Council LEED project and increases its overall sustainability.

Improve The Condition Of Old Floors

As concrete ages, surface stress, delamination, curled cold joints, and other problems can arise. Mechanically grinding the floor removes the top surface of the old concrete. Polishing strengthens it, increasing its impact and abrasion resistance.

Reduce Tire Wear

The rough, uneven texture of natural concrete causes tires to abrade, increasing wear and tear over time. A polished concrete floor system levels the joints and makes the entire surface smooth, preventing abrasion.

No Production/Plant Shutdowns

Dry-mechanically polished concrete can be put into service immediately after the process is complete. Since the process does not use toxic or hazardous chemicals, floors can often be used as soon as the project is finished.

Frequently Asked Questions (FAQ)

IS THERE A DIFFERENCE BETWEEN POLISHING NEWLY INSTALLED VS. PRE-EXISTING CONCRETE FLOORS?

The installation of a polished concrete floor has two main categories; retrofit floors and new floors. Wondering which one is perfect for you?

The choice depends on the state of your concrete floors. When working with new floors, the process does not require much work, leading to less cost. However, you may need to consider some specifications before polishing the new concrete floor.

On the other hand, retrofit floors can be polished depending on the state of the concrete. At Transpacific Building Maintenance, Inc., we can polish the concrete to any standard if it’s in excellent condition.

But, if it’s in a poor state, it needs to be ground down to the natural aggregate as the “exposure level.” So, the one that suits your floor depends on the condition of the floor.

WHAT COLORS, TEXTURES, AND FINISHES ARE AVAILABLE?

What determines the texture and finish of concrete floors is the grade of concrete used. It also determines the polishing process.

So, you have almost limitless options when choosing the colors, textures, and finishes of a new concrete floor. There are several ways to introduce color; for instance, to achieve any of your desired colors, pigment can be mixed into wet concrete.

Also, colored aggregates like marbles, stones, and pieces of glass can be added. It’s possible to color-dry concrete with water-based stain.

WHO CAN BENEFIT FROM POLISHED CONCRETE FLOORING?

- Retail Stores

- Restaurants

- Hotels

- Luxury Residences

- Warehouses

- Industrial Facilities

- Schools

- Auto Dealerships

You can see examples of polished concrete on every floor at Home Depot, Lowes, or Costco.

IS THERE A DIFFERENCE BETWEEN CEMENT AND CONCRETE?

Cement is just a concrete component, so the sidewalks found almost everywhere are not made of cement but concrete.

Presently, there is a wide variety of flooring styles and methods. Still, one of the most popular flooring solutions in recent years is polished concrete flooring.

CONCRETE AND POLISHED CONCRETE – ANY DIFFERENCE?

Cement is just a concrete component, so the sidewalks found almost everywhere are not made of cement but concrete.

Presently, there is a wide variety of flooring styles and methods. Still, one of the most popular flooring solutions in recent years is polished concrete flooring.

SO, HOW MUCH DOES IT COST TO INSTALL A POLISHED CONCRETE FLOOR?

Generally, installing a polished concrete floor is not expensive. Several factors may determine the pricing of a polished concrete floor. For instance, the decorative effects of the floor, such as scoring or staining, can increase the price.

Also, your location and how many grinding levels are needed to make the surface of the floor smooth enough are factors that may affect the price.

A common factor that often leads to a drop in the price is the size of the space. Larger spaces will cost less on a per square foot basis. Find below the cost of installing a polished concrete floor:

- The cost of a polished concrete floor, which requires just a few levels of grinding, can be as affordable as $3 to $6/sq. ft.

- Concrete floors requiring more in-depth grinding or other effects such as coloring with dyes and stains can range between $6 and $15/sq. ft.

- Since it’s often harder to obtain a consistent look when using a smaller machine on a residential floor, the typical cost for polished concrete for such space is between $6 and $15 sq. ft.